Maintaining efficient operations is crucial for businesses in today’s competitive landscape. One area that often presents challenges is managing Maintenance, Repair, and Operations (MRO) inventory. How can MRO inventory management software help streamline maintenance operations?

MRO inventory management software streamlines maintenance operations by automating inventory tracking, reducing stockouts, optimizing ordering processes, and providing real-time visibility into stock levels. This results in improved efficiency, reduced downtime, and significant cost savings.

While this answer provides a good overview, it’s important to dive deeper into MRO inventory management software’s specific features and benefits. Understanding these details can help businesses make informed decisions about implementing such systems and maximize their potential for operational improvement.

What Are The Key Features Of MRO Inventory Management Software?

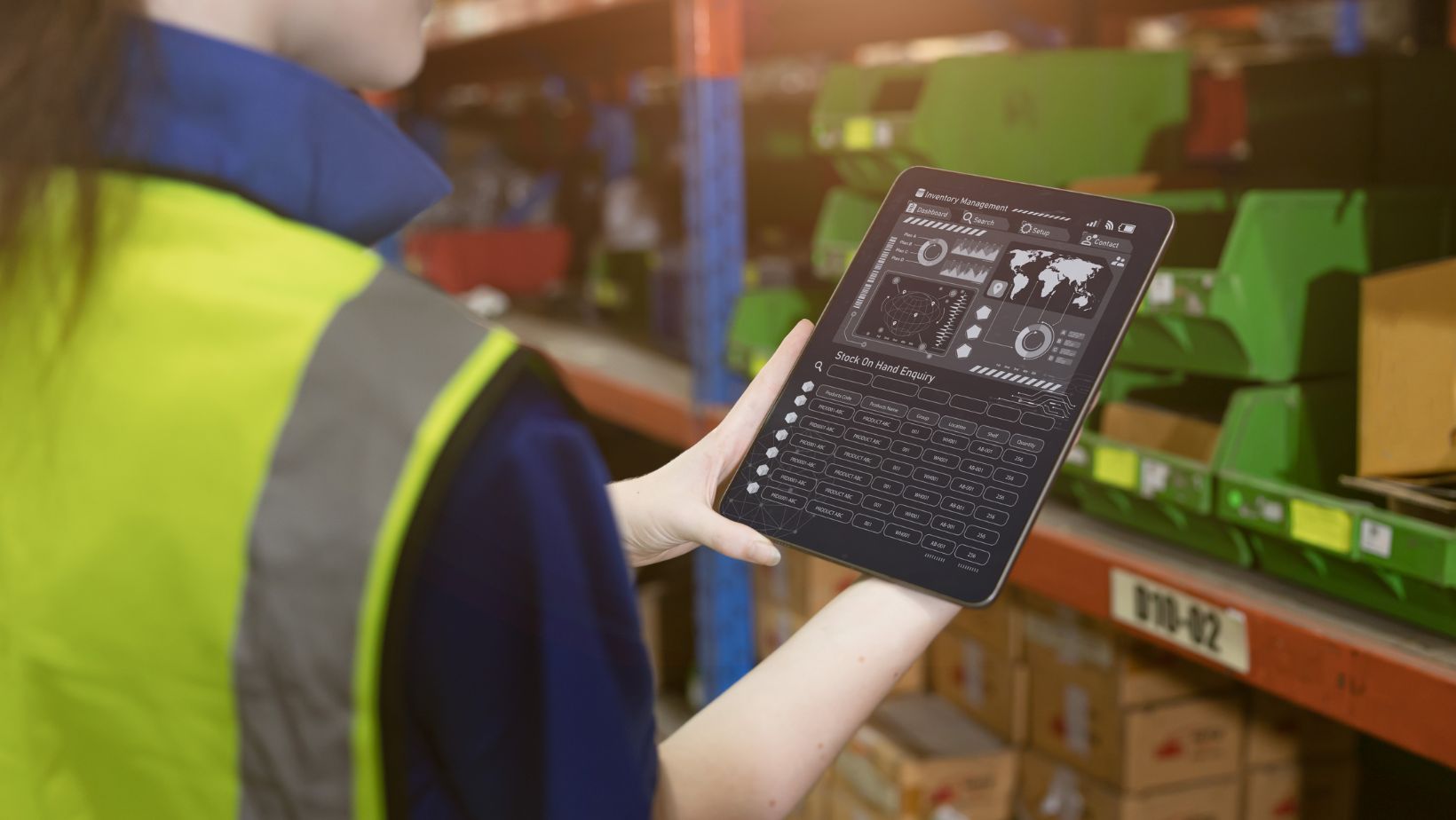

MRO inventory management software has a range of powerful features designed to optimize maintenance operations. One of the most crucial features is automated inventory tracking. This functionality allows businesses to monitor stock levels in real time, eliminating the need for manual counts and reducing the risk of human error.

Another important feature is demand forecasting. The software can predict future inventory needs by analyzing historical data and usage patterns, helping businesses maintain optimal stock levels without overstocking or understocking. This leads to improved cash flow and reduced carrying costs.

Many MRO inventory management systems also offer barcode scanning capabilities. This feature enables quick and accurate data entry, streamlining the process of receiving, issuing, and tracking inventory items. It also helps maintain an accurate inventory count and reduces the time spent on manual data entry.

How Does MRO Inventory Management Software Improve Maintenance Efficiency?

MRO inventory management software significantly enhances maintenance efficiency in several ways. First, it reduces equipment downtime by ensuring that necessary parts and supplies are always available when needed. Second, with real-time inventory visibility, maintenance teams can quickly locate and retrieve required items, minimizing delays in repairs and maintenance tasks.

The software also helps in optimizing the maintenance schedule. Providing insights into parts availability and usage patterns, it allows maintenance managers to plan preventive maintenance more effectively. This proactive approach can help prevent unexpected breakdowns and extend the lifespan of equipment.

Moreover, MRO inventory management software often integrates with other maintenance management systems, creating a centralized platform for all maintenance-related activities. This integration facilitates better communication between departments, streamlines work order processes and provides a comprehensive view of maintenance operations.

What Are The Long-Term Benefits Of Implementing MRO Inventory Management Software?

Implementing MRO inventory management software can yield significant long-term benefits for businesses. One of the most substantial advantages is cost reduction. By optimizing inventory levels, businesses can minimize carrying costs associated with excess inventory while also reducing the risk of stockouts that could lead to costly production delays.

Another long-term benefit is improved decision-making. The software provides valuable data and analytics to inform strategic decisions about inventory management, supplier relationships, and maintenance practices. Over time, this data-driven approach can lead to continuous improvement in operational efficiency.

Lastly, MRO inventory management software can contribute to better compliance and reporting. Many systems offer features for tracking expiration dates, managing warranties, and generating detailed reports. This helps maintain regulatory compliance and provides valuable insights for audits and financial reporting, leading to better overall business management.

How Can MRO Inventory Management Software Enhance Supplier Relationships?

MRO inventory management software can be crucial in improving and maintaining healthy supplier relationships. By providing accurate inventory usage and demand data, the software enables businesses to place more precise orders with their suppliers. This precision reduces the likelihood of rush orders or last-minute changes, which can frustrate suppliers and strain relationships.

Furthermore, many MRO inventory management systems include vendor performance tracking features. These tools allow businesses to monitor supplier reliability, delivery times, and quality of goods. With this information, companies can make data-driven decisions about which suppliers to retain, which to develop further relationships with, and which may need improvement or replacement.

The software can also facilitate better communication with suppliers. Some systems offer portals or integration capabilities, allowing direct information sharing with suppliers. This transparency can lead to more collaborative relationships, where suppliers become partners rather than just product providers in optimizing inventory management.

What Challenges Might Companies Face When Implementing MRO Inventory Management Software?

While the benefits of MRO inventory management software are significant, implementing such systems can come with challenges. One of the primary hurdles is resistance to change from employees. Staff accustomed to traditional inventory management methods may hesitate to adopt new technologies and processes. Overcoming this resistance often requires comprehensive training programs and clear communication about the new system’s benefits.

Data migration and integration can also pose significant challenges. Many companies have existing inventory data spread across multiple systems or even in paper records. Consolidating and cleaning this data for use in the new software can be a time-consuming and complex process. Additionally, ensuring that the new software integrates smoothly with other existing systems (like ERP or maintenance management software) is crucial for realizing the full benefits of the solution.

Another potential challenge is the initial cost of implementation. While MRO inventory management software can lead to significant cost savings in the long run, the upfront investment in software, hardware, and training can be substantial. Companies must carefully evaluate their budget and expected return on investment when choosing and implementing a system.

Lastly, maintaining data accuracy over time can be challenging. The software’s effectiveness relies heavily on the accuracy of the data it contains. Establishing and enforcing proper data entry procedures, regular audits, and ongoing training are essential to ensure the system provides reliable information and insights long after implementation.

Seizing The Initiative

Now that you understand MRO inventory management software’s benefits and potential challenges, it’s time to take action. Start by thoroughly assessing your current inventory management processes and identifying pain points and areas for improvement. Use this information to research and compare different MRO inventory management software solutions that align with your needs and challenges, considering the key features and long-term benefits we’ve discussed.